What MCU Factors Truly Matter for Scalable Wearables

China, 8th Dec 2025 – In elder care and telehealth, reliability beats novelty. The microcontroller at the heart of a watch or pendant sets that tone. It governs boot time, sensor timing, radio use, and security. Pick the wrong silicon and user trust erodes fast. Pick the right one and scale gets easier. This release explains which MCU factors matter most, the industry pain points they address, and how JiAi Intelligent Technology builds them into production devices.

The stakes are high. Custom programs fail for familiar reasons. Teams rush and hit custom smartwatch pitfalls. Scope drifts. Sleep currents run higher than planned. GNSS underperforms in dense areas. OTA breaks at the worst moment. Compliance testing finds layout flaws. Tooling slips because drafts and ribs were not validated. Each miss adds cost and delays launch.

Founded in 2015, JiAi Intelligent Technology manufactures smart wearables for seniors, safety, and telecare. The company operates an ISO9001-certified plant in Hunan. Monthly output exceeds 100,000 units. A tight supplier network supports price stability and quick turns. OEM and ODM customers receive full-lifecycle support, from concept to certification and scale.

So what MCU traits matter in practice?

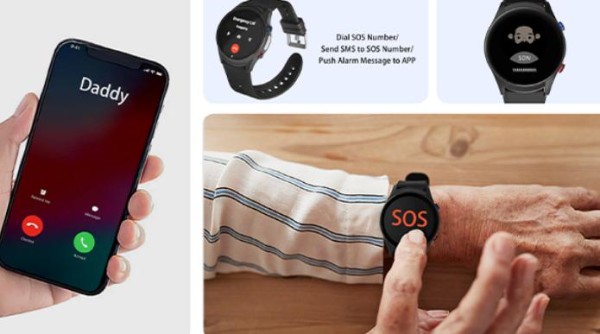

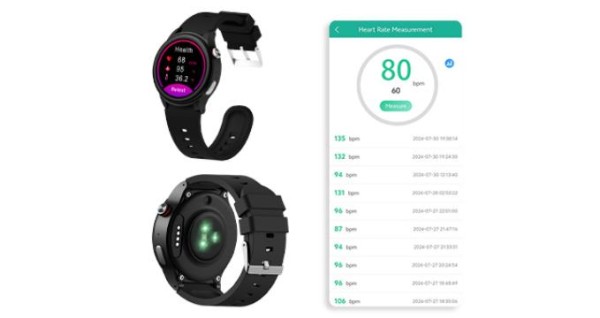

First, compute headroom at low power. Fall detection and sensor fusion need math. Yet battery life is a headline feature. The MCU must deliver DSP-like performance at low active current. Deep sleep states must wake in under a millisecond. That combination prevents missed events while keeping charge intervals long.

Second, memory with growth space. Firmware grows. Language packs, features, and logs add up. Choose flash and RAM for today and for the next two firmware cycles. Reserve space for secure OTA. This protects roadmaps and avoids risky memory refits late in development.

Third, radio fit and clean interfaces. BLE is great for phone-tethered watches. LTE Cat-M or NB-IoT suits stand-alone GPS trackers. Wi-Fi fits hubs and base stations. The MCU should host stable stacks or pair cleanly to certified modem modules over UART or SPI. Secure boot and TLS must be standard. This choice links directly to the wearable data transmission protocol you run, whether MQTT, HTTP, or a hybrid.

Fourth, peripherals for sensors. Elderly devices mix IMUs, optical heart sensors, temperature, and barometer. Multiple I²C and SPI ports, DMA, timers, and ADCs simplify integration. Rich interrupt options reduce polling and save energy.

Fifth, lifecycle and supply resilience. Elder-care deployments last years. Select MCU families with long availability and strong toolchains. This limits redesigns and keeps service stable.

These points address the hardest field realities. Battery life, latency, and stability. They also align with certification and production. Many programs underestimate both.

Consider compliance. Wearable device certification governs radio behavior, safety, emissions, and materials. CE, FCC, and RoHS shape layout and shielding from the start. Privacy laws guide logging and retention. Treating certification as an endpoint invites rework. JiAi builds a compliance matrix into the first EVT spin. Pre-scans catch hot spots. Materials meet RoHS/REACH. Labeling and manuals are prepared with each hardware revision. This reduces retest cycles and clears customs without drama.

Mechanics can bite too. Poor smartwatch mold development leads to loose fits and weak sealing. Tooling must respect antenna windows, gasket geometry, and screw torque limits. Early DFM avoids weld lines and sink marks on visible faces. JiAi pairs industrial design with mechanical and RF reviews before steel is cut. Prototype tools validate ergonomics and assembly. Hardened tools follow for mass runs. Preventive maintenance protects finish and yield across reorder waves.

Integration is another pain point. Firmware, apps, and cloud must move in lockstep. Without a shared plan, features degrade. Sensors run in default modes. OTA becomes risky. Dashboards show stale data. JiAi maintains a unified backlog that links embedded tickets to API endpoints and app features. OTA uses staged rings and rollback paths. Device logs are structured for root-cause analysis. This reduces warranty events and speeds field fixes.

Connectivity choices affect outcomes every day. MQTT lowers overhead and speeds urgent alerts. HTTP fits partner platforms and bulk uploads. Many fleets use both. JiAi provides reference stacks for either wearable data transmission protocol. TLS, certificate handling, and provisioning are standard. Power tests run in elevators, corridors, and marginal coverage. The result is predictable latency and longer uptime.

Production capacity and quality are the last mile. JiAi ships more than 100,000 units a month. ISO9001 process control keeps lines stable. Incoming inspection, in-line checks, and final functional tests protect yield. Traceability links batches to components and firmware. This discipline reduces returns and supports audits for hospital buyers.

For OEM and ODM clients, the value is a clear path:

1. Discovery and architecture. Define users, use cases, radios, sensor set, and the right MCU for Wearables. Lock budgets and test plans. Kill early custom smartwatch pitfalls by fixing scope.

2. Hardware co-design. Align RF, PCB, and enclosure. Validate battery, PMIC, and antenna placement. Bake in certification constraints.

3. Firmware and algorithms. Implement sensor drivers, fusion, SOS paths, and secure OTA. Tune power states to real duty cycles.

4. EVT/DVT/PVT and pilots. Test accuracy, ingress, drops, and long-haul power. Iterate fast. Measure before scaling.

5. Scale and sustain. Plan alternates, manage obsolescence, and maintain firmware. Keep documentation audit-ready.

Customers often ask for a checklist. Here is the short version that moves programs forward:

• Ultra-low sleep current and fast wake.

• Enough flash and RAM for two future releases.

• Stable BLE/LTE/Wi-Fi stacks and secure boot.

• Multiple I²C/SPI with DMA for sensor breadth.

• Early CE/FCC design rules and test slots booked.

• Tooling DFM completed before artwork lock.

• MQTT/HTTP plan that matches care workflows.

• Staged OTA with rollback and signed images.

This approach turns architecture into an asset. It saves battery. It cuts false alarms. It shortens certification time. It also improves user sentiment, which drives orders.

JiAi Intelligent Technology ties these threads together for brands, startups, and system integrators. The company’s hybrid model – R&D, tooling, assembly, and QA under one roof – reduces handoffs and risk. The result is faster routes from pilot to scale, with fewer surprises.

For projects targeting seniors, telecare, or safety, the headline is simple. The MCU choice is not a spec-box exercise. It is the foundation of reliability, battery life, and trust. Get it right, and scaling becomes routine. Get it wrong, and every downstream step gets harder.

For media and OEM/ODM inquiries:

WhatsApp: +86 13923492286

Phone: +86 13923492286 / +86 13517465888

Email: info@immecare.com

Address: 4th Floor, Bldg. 14, Longjun Industrial Zone, Heping Road, Longhua District, Shenzhen

Company Details

Organization: JiAi

Contact Person: JiAi

Website: https://www.immecare.com/

Email: Send Email

Contact Number: +8613923492286

Address: 4th Floor, Bldg. 14, Longjun Industrial Zone, Heping Road, Longhua District, Shenzhen

Country: China

Release Id: 08122538693