What Drives Demand for Eco Block Machines Today

China, 8th Nov 2025 – Global construction is under pressure. Deadlines are tighter. Labor is scarce. Energy costs move every week. Cities enforce strict noise and carbon rules. Developers want greener materials and faster delivery. These forces are reshaping buying plans for every Eco Blocks Making Machine on the market. They also explain why interest in a High Efficiency Block Making Machine from Qunfeng keeps rising.

The Pain Points Behind Every Purchase

Contractors list the same issues across regions. They need stable quality with fewer rejects. They must cut power use without slowing output. They struggle to hire and train operators. Noise limits slow work in urban sites. Changeovers between blocks, pavers, and tiles take too long. Unplanned downtime breaks delivery promises. Buyers still watch Automatic Block Machine Price, but they now judge value over the full life of the line.

These pain points push factories toward integrated platforms. A modern Cement Block Production Machine must combine smart controls with strong mechanics. It must run standard blocks and premium surfaces on the same line. It must be simple to learn and quick to fix. It must fit into an end-to-end process with batching, curing, and stacking.

How Qunfeng Answers The New Demand

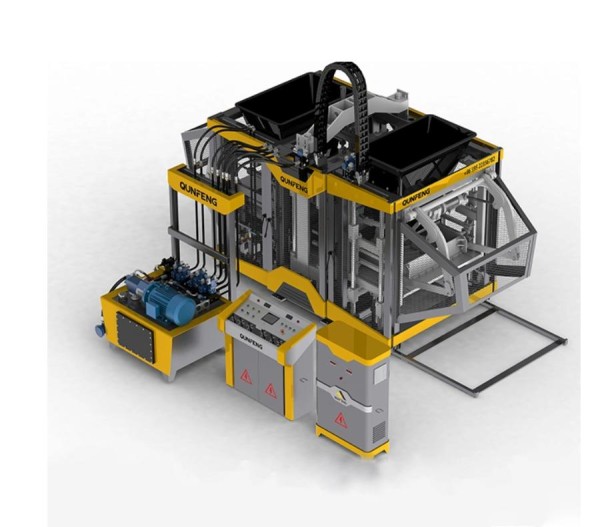

Qunfeng focuses on intelligent, efficient, and eco-friendly production. The company has spent more than 30 years refining servo motion, hydraulic power, and digital control. It now delivers an Industrial Block Manufacturing Machine that targets every major pain point. The goal is simple: consistent output at lower cost, with less noise and less waste.

- Energy, Speed, And Consistency

The platform uses a high-efficiency two-axis servo system. It delivers fast, high-frequency vibration with tight synchronization. The result is better density and a smooth surface. Power draw drops while cycle times stay short. For plant managers, that means higher yield per kilowatt.

- Fast, Flexible Hydraulics

A high-horsepower, double-pump hydraulic setup enables quick, responsive motion. Pressing, demolding, and material handling stay smooth even under heavy loads. Cycles are predictable. Throughput rises without stressing parts or operators. - Less Noise, Longer Life

Airbag clamping and engineered damping pads reduce vibration and sound. Noise levels fall, which helps plants meet local rules. Mold wear drops as well. Quieter machines support longer shifts and a safer shop floor. - Strength And Surface Quality

A double pressure head cylinder applies balanced force. Blocks reach higher strength with fewer defects. A 360-degree rotary feeder spreads mix evenly. A scraper clears excess. An anti-mix pigment system protects color layers. These steps are vital for high-grade tiles and decorative pavers. - Rapid Changeovers

An auxiliary automatic mold change system shortens downtime. Teams move from blocks to tiles quickly and safely. This is critical for small and mid-size factories that handle mixed orders. It is also useful for large plants that want more daily SKUs. - Simple, Intelligent Control

An industrial PLC sits at the core. Sensors from reputable brands feed real-time data. Operators see clear alarms and guided diagnostics. Faults are easier to trace. Training time falls. Remote support allows fast help without waiting for on-site visits. - Measurable Gains That Drive ROI

Factories want numbers, not promises. Users report a 15% saving in labor cost from intelligent control and easy operation. Electro-hydraulic integration raises output by about 20%. Suspension-type vibration and damping can reduce noise by roughly 10%. A full alarm and diagnosis suite cuts troubleshooting time by about 30%. Smart starting routines lift working efficiency by around 20%. Recipe programs saved in the controller limit human disturbance. Quality stays stable across shifts and seasons.

These gains change how buyers look at Automatic Block Machine Price. A low sticker is not enough. Decision makers now compare cost per block, maintenance hours, and energy per unit. They ask how long a mold change takes on a real shift. They review alarm logs. They measure noise at the operator station. The machine that performs across these tests wins.

Why Sustainability Accelerates Demand?

Green rules and customer expectations keep rising. Developers want lower embodied carbon and less waste. An Eco Blocks Making Machine that saves energy and cuts scrap supports these goals. Reduced noise also matters. Urban plants must protect neighbors and meet strict permits. Lower decibels can be the difference between a lost bid and a signed contract.

Flexibility is another driver. Designs, textures, and colors change by project. Quick changeovers protect margins when order sizes shrink. Clean color layers and even feeding reduce rework. A High Efficiency Block Making Machine that adapts daily gives factories a hedge against volatile demand.

Scale, Experience, And Service

Qunfeng backs its technology with scale. The manufacturing base covers about 215,000 m². The company holds more than 300 national patents. Its machines have reached over 120 countries and regions. More than 10,000 customers use the brand. This footprint supports parts supply, training, and remote service. It also brings lessons from many climates, mix designs, and building codes into each new installation.

For buyers planning a full line, integration matters. A Cement Block Production Machine should fit smoothly with batching, conveyors, curing racks, and cubing. The company provides design support so that throughput stays balanced. The result is less idle time, fewer bottlenecks, and a faster start-up curve.

What To Evaluate Before You Buy?

• Create a short, practical checklist for site trials:

• Measure energy per block at target output.

• Time a mold change from stop to first good part.

• Record noise at one meter and at the fence line.

• Review alarm categories and average time to clear.

• Check surface quality on tiles with color layers.

• Compare operator steps across shifts and teams.

• Model total cost with labor, scrap, maintenance, and planned downtime.

Use this data to compare platforms and to validate the payback of an Industrial Block Manufacturing Machine from Qunfeng.

Outlook: Why Demand Will Keep Rising

Urbanization continues. Skilled labor remains tight. Energy and materials stay volatile. Regulations grow stricter. These trends will not reverse soon. That is why demand for eco-focused, high-output equipment is strong. A smart Eco Blocks Making Machine delivers more with less: less energy, less noise, less rework, and less downtime. At the same time, it delivers more output, more flexibility, and more consistency. Factories that act now gain an edge. They shorten delivery times. They win projects that require greener methods. They protect margins when orders shift. In this landscape, a High Efficiency Block Making Machine from Qunfeng offers a clear path to stable growth.

For inquiries, email us at: group@qunfeng.com

Company Details

Organization: Qunfeng

Contact Person: Qunfeng

Website: https://www.qunfenggroup.com/

Email: Send Email

Contact Number: +8659522356789

Address: No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian

Country: China

Release Id: 08112536712