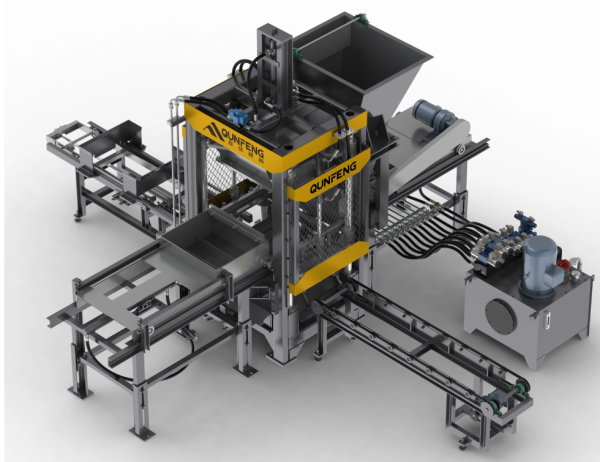

Next-Level Hollow Block Production Powered by Qunfeng Machines

China, 15th Aug 2025 – Qunfeng announces a new step forward for hollow block production. The company brings intelligent technology and high-efficiency, eco-friendly design together. The goal is simple: help manufacturers make hollow blocks faster, with stable quality, and at lower cost. Qunfeng has pursued excellence for more than 30 years. Its manufacturing base covers 215,000 ㎡. The company holds more than 300 national patents. Its solutions have reached 120 countries and regions. More than 10,000 customers use its equipment. This track record matters. It shows reliability, scale, and the ability to deliver.

• Industry Pain Points the Market Faces

The hollow block sector faces real pressure. Quality is not always consistent. Density and strength can vary by batch. Energy use is high, so costs rise when power prices rise. Many lines take too long per cycle, which limits output. Plants often have limited floor space and need compact systems. Operators want equipment that is easy to learn and maintain. Environmental rules are tighter every year. Waste and noise must go down. Investment risk is another concern. Teams need proof that an Industrial block machine can pay back fast.

How Qunfeng Addresses These Problems

Qunfeng designs every Hollow block making machine to solve these issues at the source.

• First, quality. Advanced, precise molding assures uniform compaction. Double-motor synchronous vibration drives energy where it is needed. Table vibration delivers even force across the mold surface. Blocks come out with stable size and strength. This reduces rework and scrap.

• Second, speed. A short forming cycle boosts capacity. Typical cycle times are about 15-25 seconds per press. That means more output in the same shift. The Hollow block manufacturing process becomes predictable and smooth.

• Third, efficiency. The power system is optimized for the job. Installed power is about 21.45 kW for the main machine. Intelligent control of vibration frequency, from 0-68 Hz, cuts wasted energy. Low consumption per block helps protect margins and the environment.

• Fourth, flexibility. Plants make many product types. Qunfeng machines support a wide suitable height for block from 50-250 mm. A 680×535 mm pallet size fits common formats. This range allows production of wall blocks, foundation blocks, and more. Changeovers are quick. Downtime drops.

• Fifth, footprint. Space is money. The main machine has a compact build. Dimensions are about 2800x1160x3040 mm. This helps plants fit the line into existing layouts. Expansion becomes easier.

• Sixth, simplicity. The hydraulic system is simplified. Operation is intuitive. Training time is short. Maintenance is straightforward. Wear parts are accessible. All of this lowers operating cost and risk.

• Seventh, durability. The frame and press components are designed for an 8 MPa rated pressure environment. That supports long service life. Consistent compression also improves block performance over time.

Finally, return on investment. The design aims for “low investment, high benefit.” Short cycles, low energy, and less rework improve payback. Customers can scale from small to large production without changing platforms. That reduces capital waste.

What “next-level production” looks like, step by step

The Hollow block manufacturing process under Qunfeng is clear and lean:

• Material preparation. Aggregates, cement, and water are dosed for the mix design.

• Feeding. The machine feeds material to the mold evenly.

• Compaction and forming. Synchronous vibration and pressure compact the green blocks.

• Demolding. Fresh blocks are placed on pallets with clean edges.

• Curing. Blocks move to curing, natural or steam, as needed.

• Stacking and storage. The yard layout stays efficient due to uniform sizing.

Each step supports product quality. Each step removes waste. The result is stable output and fewer stoppages.

Benefits that operators will notice on day one

• Consistent strength and size. Precise molding and even vibration fix batch-to-batch variation.

• Higher throughput. The 15-25 second cycle accelerates daily output.

• Lower energy per block. Optimized power and frequency control cut consumption.

• Easier training. Simple controls and a clean hydraulic layout speed onboarding.

• Smaller footprint. Compact dimensions help plants use space better.

• Broader product range. Heights from 50-250 mm support many SKUs.

• Lower lifecycle cost. Reliable components reduce unplanned downtime.

These gains speak to the core pain points in the industry. They make the business case strong and practical.

Qunfeng’s large manufacturing base enables quality control from end to end. The patent portfolio protects key processes and structures. Global export to 120 markets shows adaptability to many standards. Support is backed by a community of more than 10,000 users. Best practices circulate quickly. That keeps customers competitive.

Energy efficiency is not an add-on. It is part of the system. Lower power use per block means lower operating cost and lower emissions. Stable forming reduces waste. A compact footprint can lower plant infrastructure needs. All of this aligns with the company’s principle of high efficiency and environmental friendliness.

Whether a plant is starting small or scaling up, the same design philosophy applies. Flexible operation, a small occupied area, and complete functions make the equipment a smart base. As demand grows, output can grow with it. Customers do not need to change technology paths or retrain teams. They keep improving, step by step.

About the technology behind the promise

• Rated pressure: 8 MPa for steady compaction.

• Vibration frequency: 0-68 Hz for precise tuning.

• Vibration mode: Table vibration for even force.

• Pallet size: 680×535 mm for common formats.

• Block height range: 50-250 mm for flexible products.

• Cycle time: 15-25 seconds for high throughput.

• Installed power (main machine): 21.45 kW for efficient operation.

These numbers reflect a balanced system. They turn the headline promise into daily results.

Final Words

Next-Level Hollow Block Production Powered by Qunfeng Machines is more than a slogan. It is a practical path to better quality, faster cycles, lower energy use, and easier work. For manufacturers of hollow blocks, it offers a clear upgrade. For buyers searching for an Industrial block machine or a reliable Hollow block making machine, it delivers confidence and scale. With three decades of focus and a global user base, Qunfeng is ready to help producers solve today’s challenges and build tomorrow’s capacity.

Media Contact

Organization: Qunfeng

Contact Person: Qunfeng

Website: https://www.qunfenggroup.com/

Email: Send Email

Contact Number: +8659522356789

Address: No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian

Country: China

Release Id: 15082532414