How to Reduce Cement Block Machine Cost in 2025

China, 14th Oct 2025 – The construction sector faces a tough year. Input prices keep shifting. Skilled labor is tight. Environmental rules get stricter. Many producers ask the same question: how do we cut Cement Block Machine Cost without hurting quality? The answer in 2025 is clear. Tackle energy, downtime, waste, and training-at the same time. This is where QUNFENG steps in.

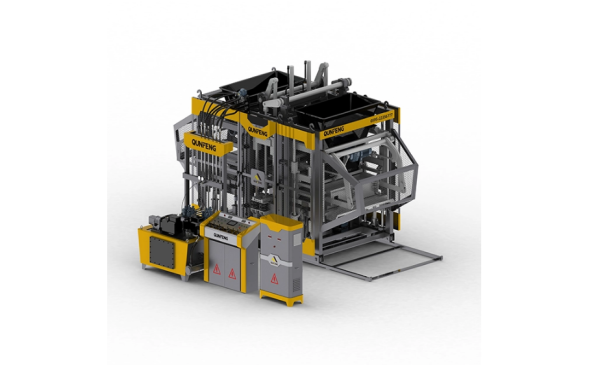

For three decades, QUNFENG has focused on building material machinery. The company designs, manufactures, and services complete lines. That includes concrete block making, AAC lines, brick cubers, and waste treatment systems. Its mission is simple. Merge intelligent technology with high efficiency and eco-friendly practice. The goal is to lift factory competitiveness, not just sell machines.

The Cost Problem Everyone Feels

Every Block machine factory knows the pain points:

• Power bills keep rising.

• Cement usage is often higher than planned.

• Molds wear out too fast.

• Quality varies shift to shift.

• Machines are loud and hard to maintain.

• Training new staff takes time and money.

• Unplanned stoppages crush output and margins.

Each issue inflates the total cost per block. A smart plan must hit all of them, not just one. In other words, treat the full cost stack, from energy to scrap.

Four Levers for 2025 Savings

1) Energy and Vibration Efficiency

Energy is the largest controllable cost. Modern Industrial Block Making Equipment needs efficient vibration with low loss. QUNFENG uses a U-shaped vibration system. It forms blocks fast and with less noise. Less noise means less wasted energy. Faster forming means more cycles per hour. The plant gets more sellable blocks from the same kilowatt hours. That lowers unit cost directly.

2) Material Use and Surface Quality

Cement is expensive. Over-consumption destroys margins. Precision feeding is critical. QUNFENG employs an anti-mixture color feeding approach. It improves paver surfaces and reduces rework. Better feeding produces compact, consistent blocks. Producers hit target strength with less cement drift. This shrinks the cement line in your cost sheet.

3) Mold Life and Maintenance

Mold wear is a hidden tax on profitability. Frequent changeovers reduce uptime. QUNFENG addresses this with airbag clamping and robust shock absorption. Airbag clamping cuts mechanical stress and lowers noise. Imported shock pads absorb impact and extend component life. The result is longer mold cycles and fewer stoppages. Operators spend less time wrenching and more time producing.

4) Automation and Usability

A good High-Quality Block Making Machine is also easy to run. QUNFENG machines use precise control systems. Interfaces are simple to learn. Start-up is quick. Changeovers are clean. Less training time means lower onboarding costs. Fewer errors mean fewer rejects. You maintain quality even when the team is new.

What This Means for Your Factory?

Let’s turn these ideas into line-item savings:

• Lower kWh per pallet: Efficient vibration and fast forming cut energy per block.

• Lower cement variance: Consistent compaction and feeding reduce over-design.

• Lower maintenance cost: Airbag clamping and shock absorption lengthen mold and part life.

• Lower scrap and rework: Stable compaction raises first-pass yield.

• Lower labor per unit: Simple operation speeds training and reduces manual tweaks.

• Higher uptime: Fewer stoppages push more pallets through each shift.

Stack these gains and the reduction in Cement Block Machine Cost becomes substantial. The effect compounds when you run multiple shifts. It also scales across regional plants.

Fit for Different Plant Sizes

Not every site runs at mega scale. Many markets need agility. A Small Block Making Machine still deserves top-tier efficiency. QUNFENG offers options for compact footprints with real throughput. The same engineering logic applies. Energy savings, precise compaction, material control, and low noise. Smaller factories can hit quality goals without oversized power or staff. This helps local builders meet fast timelines and cost targets.

Global Proof, Not Just Theory

QUNFENG began in 1995. Since then, it has built a large base. The company holds more than 300 national patents. It has served over 10,000 customers. Systems operate in 120 countries and regions. That scale matters. Global feedback tightens every design loop. Service teams refine training and maintenance guides. Spare parts networks mature. All of this reduces risk and downtime for new buyers.

Sustainability as a Cost Lever

Regulations will not relax in 2025. Noise control and dust control are common pain points. Efficient vibration lowers noise at the source. Better compaction reduces breakage and waste. Smarter feeding limits spills and color bleed. These are sustainability wins that also save money. In many markets, compliance now unlocks projects. A machine that helps you pass audits is a revenue tool.

What to Ask Before You Buy

If you plan to invest in Industrial Block Making Equipment, use this checklist:

(1)Can the vendor prove lower kWh per pallet?

(2)Is vibration technology fast and quiet?

(3)How does the feeding system prevent color mixing?

(4)What protects molds and frames from shock?

(5)How quick is operator training?

(6)What is the service and parts footprint?

(7)Can the machine maintain tight tolerances in heat and cold?

(8)How will it integrate with your curing, handling, and cubing?

QUNFENG can map each question to a tested feature and a field result. The company’s approach blends intelligent controls with efficient mechanics. It turns theory into daily savings on your line.

Why This Matters Now?

Construction demand is uneven across regions, yet competition is intense. Buyers want strong, precise, and attractive blocks. Schedules are tight. Budgets are tighter. A Block machine factory that cuts waste and boosts uptime wins bids. A machine that stabilizes quality protects your brand. A partner with deep service support reduces surprises. This is how you reduce Cement Block Machine Cost in 2025 and keep it down.

About QUNFENG

QUNFENG is a global provider of High-Quality Block Making Machine solutions and full production lines. The company also supports AAC production, brick cubing, and construction waste treatment. Its philosophy is “intelligent technology, high efficiency, and environmental friendly.” From compact systems to high-throughput lines, QUNFENG tailors equipment to the needs of each market. The result is lower unit cost, steady output, and reliable quality-day after day.

Media and Sales Inquiries

• Email: group@qunfeng.com

• Tel: +86-595-22356789

• Fax: +86-595-22356788

• WeChat / WhatsApp: +86-18150503129

By focusing on energy efficiency, material control, durability, and ease of use, producers can drive down Cement Block Machine Cost. Whether you operate a large plant or run a Small Block Making Machine, the path is the same. Choose proven engineering. Choose responsive service. Choose QUNFENG.

Company Details

Organization: Qunfeng

Contact Person: Qunfeng

Website: https://www.qunfenggroup.com/

Email: Send Email

Contact Number: +8659522356789

Address: No.11,Zhitai Road,Quanzhou Economy&Technique Development Zone,Fujian

Country: China

Release Id: 14102535361