How Advanced Engineering Ceramics Solve Wear-Resistance Failures

China, 14th Oct 2025 – Wear-resistance failures still threaten productivity across factories, labs, and data infrastructure. Bearings seize. Guides deform. Connectors drift out of spec. Unplanned downtime follows. Many teams turn to Engineering Ceramics to break this cycle. Materials like zirconia deliver high hardness, fracture toughness, and chemical stability. They keep dimensions stable under heat and load. They also enable precise alignment in optical and electronic systems.

UPCERA is helping manufacturers make this shift at scale. Founded in 2003, the company became the first in China to independently develop zirconia ceramic sleeves for optical communication. Since then, UPCERA has focused on strict quality control and repeatable performance. Today, its sleeves and ferrules support optical communication connectors, optical modules, computing power centers, and data centers worldwide. That track record matters when you need a Ceramic Material Supplier that can support both volume and precision.

The pain points engineers face

Engineers report recurring issues:

• Fast wear in high-friction zones.

• Surface damage that raises particle counts and contamination risk.

• Thermal cycling that shifts alignment and tolerance.

• Metal corrosion in harsh media.

• Electrical noise and magnetic interference around sensors.

• Inconsistent supply and long lead times for niche parts.

Each issue creates scrap and rework. Each also blocks throughput gains. The result is higher cost per unit and slower launches.

Why Engineering Ceramics Change the Equation

Ceramics attack these pain points directly. Zirconia brings high strength and fracture toughness. It resists wear and abrasion. It stays dimensionally stable under heat. It is chemically inert and corrosion resistant. It is electrically insulating and non-magnetic. It machines to tight tolerances with the right processes. The right Ceramic Material Supplier must combine material science with stable manufacturing. This is where UPCERA focuses.

1)Solving Machining Hurdles in Ultra-hard Materials

Ultra-Hard Ceramic Machining is not simple. Edge chipping can occur. Micro-cracks can seed future failure. Rough surfaces raise friction and heat. Tolerance drift causes assembly scrap. UPCERA addresses these risks with advanced processing and metrology. The team controls grain structure, densification, and finish. Tight tolerance control reduces variation lot to lot. The result is smoother mating surfaces and more stable alignment. That improves wear life and signal integrity.

2)Wear-Resistant Ceramic Parts for Uptime

In high-load or abrasive loops, Wear-Resistant Ceramic Parts last longer than many metals and polymers. UPCERA designs bushings, guides, seats, nozzles, and sleeves to match the duty cycle. Stable surfaces reduce friction and heat. Corrosion resistance preserves geometry in aggressive media. Electrical insulation protects nearby circuits. Non-magnetic behavior suits sensitive instruments. Longer life means fewer changeovers and less downtime.

3)Precision Ceramic Rod for Mechanical and Electrical Roles

The Precision Ceramic Rod is a workhorse in structural and insulation roles. Zirconia and alumina rods offer high strength and hardness. They keep geometry under temperature swings. They resist acids and alkalis. They insulate at high voltage. Smooth surfaces and tight tolerances reduce wear on mating parts. UPCERA supplies standard sizes and custom builds. Typical uses include guide pins, spacers, standoffs, shafts, and protective sleeves in precision equipment and corrosion-resistant pipelines.

4)Custom Zirconia Parts for Demanding Applications

UPCERA’s Custom Zirconia Ceramic Parts address unique geometries and tight envelopes. Zirconia (ZrO₂) combines strength, fracture toughness, and thermal stability. These parts perform under impact, cyclic loading, and heat. They maintain surface integrity in high-friction environments. They also provide electrical insulation and magnetic neutrality. Engineers select them for medical devices, precision instruments, semiconductor tools, industrial machinery, aerospace, automotive, and chemical processing. Customization enables exact fits and faster integration.

5)Custom Ceramic Ferrules for Optical Integrity

Fiber systems need consistent alignment and low loss. Standard components do not always fit new designs. UPCERA builds Custom Ceramic Ferrule solutions from high-purity zirconia. Engineers can specify ID, OD, length, chamfer, bore count, and end styles. Options include step-end, tapered end, and metal shank. The goal is stable alignment, low insertion loss, and low return loss over many cycles. These ferrules support lasers, sensors, custom transceivers, and non-standard connectors. They also suit metrology and hybrid electro-optic assemblies.

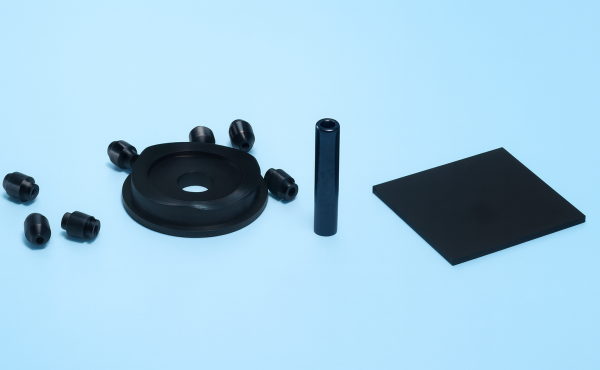

6)Black Zirconia Parts Where Function Meets Design

Some applications require a dark, non-reflective surface. Black Zirconia Ceramic Parts provide that look without sacrificing strength or wear resistance. They balance mechanical performance with optical benefits. The parts remain stable under heat and in corrosive media. They are electrically insulating and non-magnetic. Engineers use them in precision machinery, medical devices, electronics, optical systems, and premium consumer products. Complex geometries and tight tolerances are available.

Proven Supply and R&D Depth

Scale matters when moving from prototype to production. In 2021, we began independent operations and continued to focus on precision structural ceramics. Today, UPCERA supplies customers in over 100 countries and regions. The company’s R&D draws on ceramics expertise originating from Tsinghua University. Deep collaboration with Sinocera supports source R&D and quality control. UPCERA has independently developed more than ten categories of ceramic materials and a broad portfolio of products. That foundation helps teams launch faster with less risk.

What this means for manufacturers? By shifting wear-critical interfaces to ceramics, teams gain predictable life and cleaner processes. Engineering Ceramics can hold alignment and reduce drift. Ultra-Hard Ceramic Machining done right enables tight tolerances and smooth finishes. Wear-Resistant Ceramic Parts cut downtime. A Precision Ceramic Rod adds strength and insulation in compact spaces. With a reliable Ceramic Material Supplier like UPCERA, these gains become repeatable at scale.

Next steps

If you face wear-related failures, start with a targeted review. Map the highest-cost replacements and the dirtiest steps. Identify the interfaces with heat, friction, or corrosive media. Consider a ceramic retrofit where it pays back fastest. UPCERA can evaluate part geometry, surface finish, and mating materials. The team can propose Engineering Ceramics options, from standard rods to Custom Zirconia Ceramic Parts and Custom Ceramic Ferrule solutions. For optics-heavy systems, zirconia sleeves and ferrules protect alignment in dense connectors and modules. For motion systems, guides and bushings in zirconia stabilize load paths and cut wear.

About UPCERA

Founded in 2003, UPCERA focuses on quality and performance in advanced ceramics. The company is recognized for zirconia ceramic sleeves and ferrules in optical communication. Products are used in optical connectors, optical modules, computing power centers, and data centers. UPCERA provides end-to-end support as a global Ceramic Material Supplier for Wear-Resistant Ceramic Parts, Precision Ceramic Rod, Custom Zirconia Ceramic Parts, and Ultra-Hard Ceramic Machining services.

Media Contact:

UPCERA – Advanced Engineering Ceramics Solutions

• Email: gtsw@upcera.com / luo.fz@upcera.com

• Phone: 0755-86008635

• Mobile: +86 15572499372

[General inquiries and technical support available upon request.]

Company Details

Organization: UPCERA

Contact Person: UPCERA

Website: https://www.proupcera.com/

Email: Send Email

Contact Number: +8615572499372

Address: 5F, Block B, Tsinghua Information Port, No.1 Songpingshan New East Road, Xili Street, Nanshan District, Shenzhen, Guangdong, China

Country: China

Release Id: 14102535347