Cloom Tech Unveils Custom Ribbon Cable Assemblies for High-Density Electronics

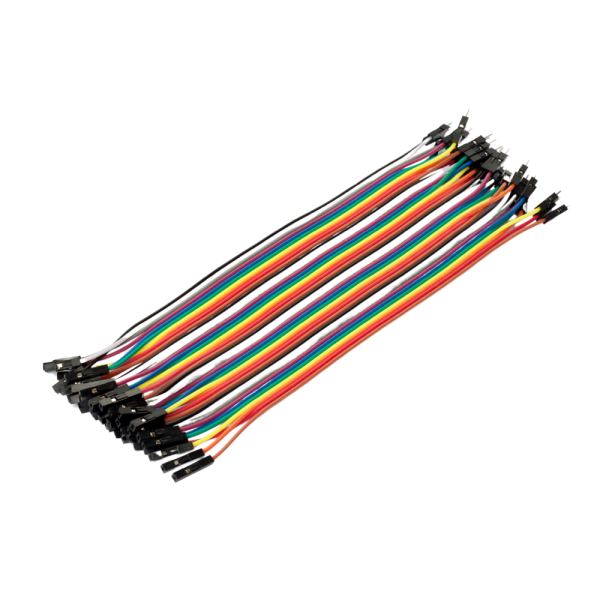

Cloom Tech, a Florida-based, engineering-led manufacturer specializing in custom wire harnesses and cable assemblies with in-house design support, prototyping, production scaling, and compliance documentation for automotive, robotics, medical device, and aerospace programs, has announced newly developed custom ribbon cable assemblies for high-density electronics. The announcement signals continued adoption of flat, low-profile interconnects for compact systems requiring consistent electrical performance and controlled routing across space-limited enclosures.

The assemblies combine flat-profile conductors with selectable pitch, jacket materials, and shielding options to align with mechanical and electrical constraints common to dense enclosures. Engineering support spans prototype through production, with documentation structured around drawings, specifications, and verification procedures familiar to quality and compliance teams. Emphasis is placed on connector compatibility, bend-radius guidance, and strain-relief placement to help maintain form factor without compromising serviceability.

“This introduction reflects steady demand for compact interconnects that balance manufacturability with predictable performance,” said Ivy Zhao, spokesperson for Cloom Tech. “The assemblies are configured to support traceable materials, consistent termination practices, and measured electrical characteristics suitable for high-density boards and harness routes.”

Design considerations include impedance management for high-speed signals, separation strategies for power and data lines, and options for shielding coverage where electromagnetic exposure is a concern. Flat construction aims to simplify cable tracing and stacking inside crowded housings, while controlled pitch selections allow routing through narrowly spaced channels. Termination methods encompass crimp, insulation-displacement, and soldered interfaces, selected according to connector systems, current requirements, and expected vibration profiles.

Attention to qualification and validation has been incorporated into the production pathway. Sampling plans, continuity checks, and pull-test thresholds are prepared to align with project needs, with options for environmental screening such as temperature cycling and humidity exposure when required by end-use standards. Documentation packages can include certificates of compliance, material declarations, and first-article inspection records to support traceability and auditing.

From a manufacturing standpoint, process control focuses on repeatability. Conductor alignment, cut-length accuracy, and jacket integrity are monitored through in-process inspections and final acceptance checks. Labeling conventions are available for assembly identification and maintenance reference, assisting field service teams during installation and replacement cycles. Consideration is also given to routing aids such as clips and guides that preserve cable shape inside enclosures where airflow and component proximity influence placement.

The product scope is positioned to complement existing harness and assembly work across transportation, automation, healthcare technology, and flight hardware. Integration paths include board-to-board links, display and sensor interconnects, battery management connections, and control-panel harnessing where planar cabling can reduce bulk. By keeping bend profiles predictable and minimizing cross-section height, the assemblies are suited to stacked card cages, compact controllers, and portable instruments.

“Future development will examine finer-pitch variants, additional high-temperature polymers, and extended test coverage for signal integrity,” Zhao added. “The roadmap centers on incremental improvements in reliability, manufacturability, and documentation so that complex systems can maintain consistency over longer service intervals.”

The announcement arrives amid continued miniaturization in electronics and a steady push toward modular subsystems. Flat ribbon cabling remains a practical choice where uniform conductor spacing, planar routing, and low profile are beneficial. For projects governed by strict environmental and regulatory frameworks, the availability of defined materials and verification steps supports predictable change control and procurement planning.

Cloom Tech operates from 9251 NW 112th Ave, Medley, FL 33178, USA, and provides support from early design discussion through to production transition. Service scope includes drawing reviews, prototype builds for fit and electrical checks, and production scaling guided by documented work instructions. The company’s approach emphasizes coordination with customer engineering teams, contract manufacturers, and compliance personnel to align interconnect details with broader system requirements.

For media inquiries regarding Custom Ribbon Cable Assemblies, Cloom Tech may be contacted at +1 863 434 8447 or sales@cloomtech.com.

Media Contact

Organization: Cloom Tech

Contact Person: Ivy Zhao

Website: https://cloomtech.com/

Email: Send Email

Contact Number: +18634348447

Address: 9251 NW 112th Ave

Address 2: Medley, FL 33178

Country: United States

Release Id: 20082532353