Butler Technologies Unveils Next Gen Flexible Heaters for EV and Medical Applications

Flexible printed heaters are ultra-thin, bendable heating elements used in electric vehicles (EVs) and medical technology. These heaters offer uniform, energy-efficient heating, ideal for battery management, seat warmers, wearable therapy devices, and smart bandages. Butler Technologies leads the industry by developing advanced, customizable heater solutions, including self-regulating PTC designs. With applications in mobility and healthcare growing, flexible heaters are becoming essential for the future of compact, connected devices.

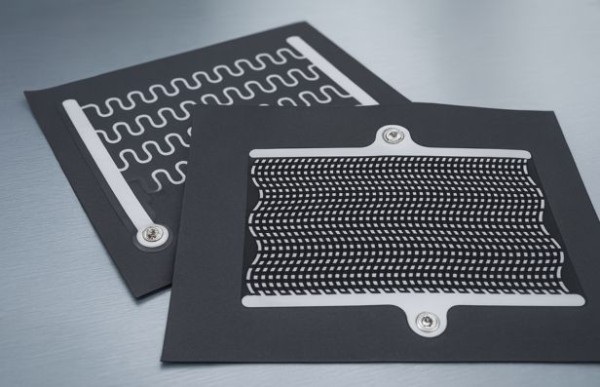

West Wayne, Pennsylvania, United States, 1st Aug 2025 – Flexible heaters are thin, bendable heating elements made by printing conductive and resistive inks onto plastic films. Unlike bulky wire-based heaters, these printed heaters are typically only 0.05–0.76 mm thick and can conform to complex shapes. For example, Butler Technologies (BTI) notes their printed heaters have a “thin, flexible, and sometimes stretchable” form factor that can even flex with the human body.

These heaters are already used in apparel, aerospace, automotive, and medical devices, and demand is rising rapidly, especially as electric vehicles (EVs) and advanced medical technologies require compact, efficient heating solutions.

Overview of Flexible Heaters

Flexible printed heaters are essentially heating films. Conductive busbars and resistive ink patterns are screen-printed onto a polymer substrate (such as polyester, polyimide/Kapton, or thermoplastic polyurethane. When voltage is applied, these printed traces generate heat via Joule heating.

By choosing inks and patterns precisely, engineers can tailor the heater’s performance. The result is an ultra-thin, bendable film heater that can be laminated onto fabrics, plastic panels, or even embedded within devices. Because they are so thin and flexible, these heaters can go in places traditional heaters can’t – for example, inside wearable garments or molded into car parts.

Flexible heaters come in two main styles: fixed-resistance heaters (with a nearly constant resistance) and PTC (positive-temperature-coefficient) heaters. PTC heaters use carbon-based inks that automatically limit their temperature – as the heater warms up, its resistance rises, preventing overheating.

Butler Technologies and others offer both types: fixed-resistance printed heaters for controlled warmth, and PTC printed heaters that self-regulate to a set temperature. In practice, a printed flexible heater can be built as a thin stack of layers (adhesive, printed busbars, heating ink, cover film), much like a flexible circuit.

Alt Text: Person wearing a flexible heater jacket for cold weather

Key Benefits of Flexible Heaters

1. Ultra-Thin & Conformable

Flexible printed heaters are typically less than 0.1 mm thick, making them ideal for space-constrained and irregularly shaped applications. Their ultra-thin profile allows seamless integration beneath fabrics, within plastics, or onto curved surfaces.

When printed on thermoplastic polyurethane (TPU) films, they can flex and stretch with the underlying material, making them especially suitable for wearables and dynamic environments.

2. Uniform, Efficient Heating

The use of resistive inks enables engineers to design precise heating patterns that eliminate hotspots and ensure even heat distribution. This enhances both safety and user comfort. These heaters are highly energy efficient and compatible with low-voltage power systems, making them suitable for battery-powered applications.

Positive Temperature Coefficient (PTC) heaters provide an additional layer of control by automatically regulating their temperature, eliminating the need for external thermostats.

3. Lightweight & Portable

Since flexible heaters do not rely on bulky coils or metal components, they are lightweight and perfect for portable devices. They operate efficiently on 12 to 24-volt battery packs, delivering reliable heating performance while maintaining minimal weight.

Their thin and light structure makes them particularly well-suited for integration into garments and other wearable technologies, without compromising mobility or comfort.

4. Safe & Durable

Flexible heaters are designed to operate at low voltages, significantly reducing the risk of electric shock or fire. They are also robust and washable, making them ideal for textile-based or wearable applications.

Printed with stable conductive inks such as silver or carbon, these heaters offer a long operational life. PTC variants further enhance safety by self-limiting temperature to prevent overheating, ensuring consistent and reliable performance over time.

Alt Text: Flexible Heater in Car Seats

Flexible Heaters in Electric Vehicles (EVs)

1. Battery Thermal Management

Flexible printed heater films are embedded inside electric vehicle (EV) battery modules to maintain optimal operating temperatures. By delivering consistent heat, these heaters help improve vehicle range and charging efficiency, particularly in colder climates where battery performance can decline.

Their ability to conform to the exact shape of battery cells ensures efficient and localized heating. Additionally, graphene-enhanced PTC inks enable the heaters to warm up quickly while automatically regulating temperature to prevent overheating, ensuring both safety and performance.

2. Cabin and Seat Heating

Thin and flexible printed heaters are commonly integrated beneath seat upholstery and inside steering wheels to provide rapid and even heating. These heaters offer enhanced passenger comfort while drawing minimal power, which is crucial for preserving overall EV efficiency.

Butler Technologies provides PTC heater design solutions that are ideal for automotive interiors. By replacing older, energy-inefficient heating methods, these advanced systems contribute to extended EV driving range and a more comfortable driving experience.

3. Defrosting and Sensor Protection

Flexible film heaters are also applied to windshields, mirrors, and external sensor housings to prevent fog buildup and ice formation. Transparent heater layers allow for fast, uniform defrosting without creating hotspots that could affect visibility.

These heating elements are essential for maintaining the functionality of LiDAR systems, cameras, and other sensors used in autonomous and semi-autonomous vehicles, ensuring they operate reliably under all weather conditions.

Alt Text: Flexible Heater Integrated in Back Belt for Pain Relief

Flexible Heaters in Medical Technology

1. Wearable Therapeutic Devices

Flexible printed heaters are increasingly used in wearable medical devices such as braces, wraps, and garments to deliver localized heat therapy. These devices help alleviate pain, improve circulation, and enhance overall comfort.

Printed on stretchable TPU films, the heaters conform to the shape of the human body and maintain flexibility during movement. Their lightweight design and compatibility with battery power make them well-suited for mobile or at-home therapy applications.

2. Patient Warming Systems

Medical environments such as neonatal care units, emergency response settings, and hospital beds use flexible heaters to maintain patient body temperature. These systems often rely on PTC materials to ensure gentle, self-regulated heating that eliminates the risk of overheating.

Compared to traditional electric wire blankets, thin-film printed heaters provide improved comfort, uniform heating, and better integration with patient care protocols.

3. Smart Bandages and Heating Pads

Flexible printed heaters are also embedded into smart bandages and heating pads designed to accelerate wound healing and post-surgical recovery. These heaters can be custom-shaped to target specific treatment areas, offering precise and localized heat.

In some cases, thermotherapy wraps combine compression with active heating, offering dual benefits in a single device for pain management and tissue repair.

4. Other Medical Applications

Beyond traditional uses, flexible heaters are found in surgical garments, infusion fluid warmers, and diabetic foot therapy systems. When integrated with temperature sensors, they enable real-time monitoring and feedback, improving patient safety and treatment effectiveness.

Butler Technologies has pioneered several advanced applications in this area, including wound recovery badges that incorporate printed heaters within medical films.

Technological Trends and Future Directions

1. Advanced Materials

The use of innovative materials such as Kapton substrates and graphene-based conductive inks is elevating the performance of flexible heaters. These materials enhance durability under extreme conditions, including repeated washing or high heat exposure.

Looking ahead, the industry is exploring the potential for biodegradable and highly stretchable substrates that could further expand applications in healthcare and sustainability-driven sectors.

2. Self-Regulating (PTC) Designs

Heaters designed with Positive Temperature Coefficient (PTC) properties offer automatic temperature control by increasing resistance as they warm. This built-in regulation improves operational safety by eliminating the need for external thermostats.

These heaters heat up quickly and reduce power draw once the desired temperature is reached, making them efficient and safe for medical and consumer applications.

3. Smart Integration (IoT)

Flexible heaters are now being integrated with sensors and wireless technologies, transforming them into intelligent systems.

This integration enables real-time data transmission and closed-loop temperature control, which is especially valuable in remote patient monitoring and advanced electric vehicle systems.

Smart heaters are paving the way for new levels of personalization and automation in both the healthcare and automotive industries.

4. Miniaturization & Customization

Recent advances in printing technology enable the creation of more intricate and compact heater layouts. This enables the creation of highly specialized heating components for small medical devices, wearables, and irregularly shaped vehicle components.

Roll-to-roll manufacturing supports both rapid prototyping and scalable production, making it easier to meet diverse industry needs.

5. Growing Markets – EVs and Medtech

Flexible heaters are becoming essential in rapidly growing sectors like electric vehicles and healthcare. In EVs, they are used for battery and cabin heating, improving efficiency and performance.

In the medical field, they are integrated into smart wearables, patient warming systems, and recovery aids. Their compact design, low energy consumption, and adaptability make flexible heaters a key solution in the pursuit of sustainability and innovation.

Alt Text: Butler Technologies brand logo

Butler Technologies’ Role in the Future of Flexible Heaters

Butler Technologies, Inc. is a recognized leader in the development of flexible printed heaters. With decades of expertise in printed electronics, the company designs, fabricates, and assembles custom thermal and interface solutions across industries.

What makes Butler Technologies stand out is its ability to create ultra-thin, stretchable heaters that can be discreetly integrated into garments, medical devices, and automotive interiors. These printed heaters offer targeted, uniform heat while remaining lightweight and flexible. Butler Technologies’ offerings include both fixed-resistance and self-regulating PTC heater options, suited for everything from wearable tech to industrial applications.

The company partners with automotive manufacturers and healthcare innovators to deliver custom heating solutions like seat warmers, therapeutic braces, and advanced wound care systems. A notable example includes the integration of Butler Technologies’ heater technology into Team USA’s Olympic jackets to provide athletes with consistent warmth in cold conditions.

With ongoing research into advanced materials and printing techniques, Butler Technologies is helping drive the next generation of heating solutions for electric vehicles and medical technology.

Flexible Heaters Driving Innovation in EVs and Medical Devices

As electric vehicles and medical wearables become more advanced, flexible printed heaters are proving to be a key technology. Their thin form factor, precise control, and energy efficiency support the growing need for lightweight, responsive thermal solutions.

Butler Technologies plays an essential role in meeting this demand. By enabling smarter thermal management in both mobility and healthcare sectors, the company helps bring comfort, safety, and performance to the next level of product design. Flexible heaters are no longer optional add-ons; they are integral to the future of intelligent, connected devices.

Media Contact

Organization: Butler Technologies

Contact Person: Courtney Houtz

Website: https://butlertechnologies.com/

Email: Send Email

Contact Number: +17245082016

Address: 231 West Wayne St.Butler, PA 16001, USA

City: West Wayne

State: Pennsylvania

Country: United States

Release Id: 01082531747