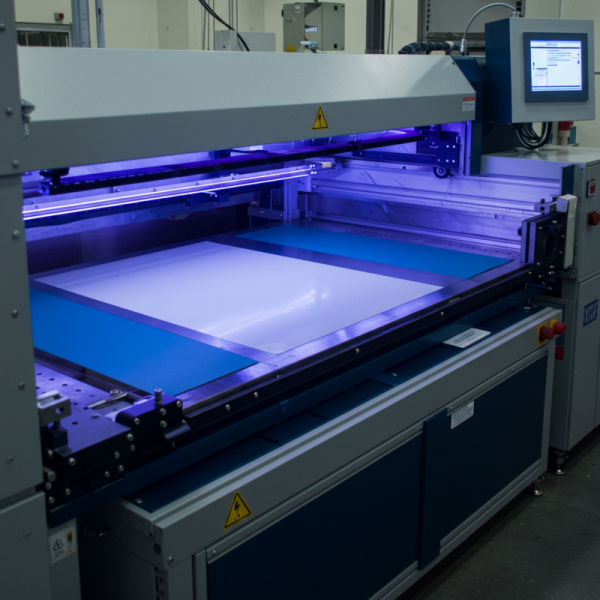

High Intensity OEM UV Solutions Portable systems to create huge UV exposure

China, 21st Aug 2025 – The value of the high-intensity and OEM UV solutions has recently been on the rise in numerous industries, such as the healthcare, electronics, and manufacturing industries, alongside material processing in the context of progressive technological advancement. The novel technologies provide precise, consistent, and fast exposures of ultraviolet light, especially in the wavelength range (365- 405nm), and hence can be implemented for many uses such as curing, sterilization, and even material inspection.

UV Appliances for small-scale optimal efficiency

Modern industrial systems regularly require small, however productive applications. The factory of mini UV equipment is to deliver high UV power along with a minimal physical envelope. They are compact in design, therefore fitting within OEM equipment or even lab applications. Compact UV devices are designed such that they do not compromise on performance. These devices provide a consistent output in the selected range of wavelength within a required area of therapy using the newest technology of LED and optical technology.

Wide-Area UV Exposure: Performance Equivalency

Wide area UV exposure is one of the headline features of high-intensity UV systems. By covering more surfaces, the systems have high throughput with shorter processing times. This matters a lot, especially where high volume is involved. Whether this is to cure adhesives or coatings, or even in practice surface sterilization, Wide-area UV exposure ensures that all parts of a substrate or surface to be treated are exposed in an effective and uniform manner by the UV. This restricts the flaws and promotes the quality of the products, and ensures sensible applications.

The technical advantage associated with OEM high-intensity UV Solutions

The following are some technical benefits of a high-intensity UV system:

- Flexibility: Within wavelength section (365-405nm, wavelength freedom works best when it comes to exposing a target photo initiator or biologic, e.g., curable efficiency or sterilization.

- Energy Efficiency: Advanced compact UV sources based on LEDs consume less energy as compared to the traditional mercury lamps, and they conserve the work costs and also ensure a standard efficiency.

- Durability/Longevity: These UV systems are intended to run constantly, thus they may have high thermal isomorphic electrical design, stainless steel, and long-life LEDs.

- Custom combination: OEM solutions can be minimally customized to provide the flexibility that the industrial designers desire in a particular machine interface or exposure area, or a workflow application.

Ability to enjoy equal and large-scale exposure of big areas

The array of solutions that businesses interested in upgrading or implementing the UV technology into their businesses have at their disposal includes the small and configurable solutions, which exclusively hinge on the operational requirements of a particular business. Collaboration with the well-known suppliers ensures that the devices meet high standards of safety and level of performance.

An investment in The Future of UV Technology

Under the stress of expediency, effective time and accurate treatment are increasing in the industries; high-intensity OEM UV solutions would become the standard today. They only fit outstandingly in the organization that is keen to amplify its productivity fronts in most areas towards the high quality and safety provisions given their production of their particular wavelength (365 to 405 nm), as well as low volume and large exposure area.

Media Contact

Organization: UVET

Contact Person: UVET

Website: https://www.uvndt.com/

Email: Send Email

Contact Number: +8613923758020

Address: address1802, Bldg A, Baian Center, Nancheng District, Dongguan 523073, China.

Country: China

Release Id: 21082532703